AS P Series

New model of small-sized screw compressor with low noise and vibration that can be installed in narrow space

Characteristics of AS P Series (Belt Drive Type)

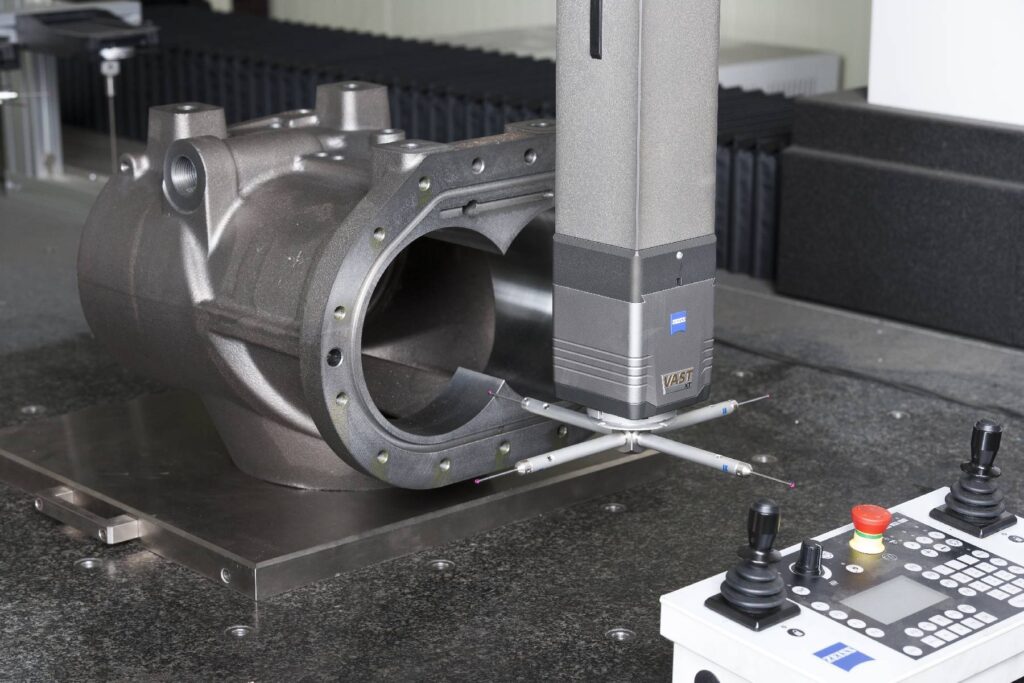

Powerful AIREND

- Application of latest airend [made inGermany]

- Removal of causes of oil and compressed air leakage through integration with components

- High efficiency and quiet operation noise through application of high efficiency and low-speed rotationairend

High efficiency and low noise cooling fan

- Application of steel fan with excellent durability and efficiency

- Application of outer rotor fan

- Discharge air volume maximised by the installation of a separate tan motor

Smart & Intelligent Controller

- Two or more languages can be selected [Korean / English, English / Russian] for display of operation status and alarm text

- Various alarm functions, equipment protection functions and driving history monitoring function[60 iems]

- Alarm functions -maintenance lime, discharge temperature excess, pressure excess, etc.

- Equipment protection functions – discharge temperalure excess, pressure excess, overloading of the main motor, emergency stop, etc.

Combination Cooler

- Outstanding cooling performance under bad conditions based on optimal fin tube for cooling efficiency

- High durability cooler designed to withstand up to 15 bar [made inKorea]

Main Motor

- Application of totally enclosed high efficency motor

Oil leakage prevention design

- Stainless flexible hose used for complete blocking of vibration and prevention of oil leak

Inverter (VSD) Air Compressor is a necessity, not a choice!

Air demand analysis device (SCADAR SYSTEM) possessed by COAIRE offers a service for optimal compressed air system needed by your company

*We analyze your compressed air demand and perform energy diagnostics

The sequence of energy reduction project [SCADAR SYSTEM]

Dispatch of compressed air system engineer

Analysis of the current system and compressed air usage pattern of the customer Data collected according to the configured cycle for at least 7 days and at most 14 days

Installation of air demand analysis device (SCADAR)

Determination of necessary conditions through the on-site survey on the customer’s air compression system and negotiation on details

Analysis on air compressor usage pattern

Information collected by air demand analyzer is used to submit analysis data on actual usage or usage pattern of each air compressor

Precise diagnostics and recommendation of optimal product composition

Consulting and data submission on the expected reduction in power cost and investment recollect on the period when the inverter air compressor is implemented

Air Demand Analysis Device

Air Demand Analysis Device [Air Demand Analysis Kit]

- Actual amount of air use or type of use has analyzed at the site

- Optimal product composition recommended as appropriate for conditions of use

- Data submitted by presenting power saving effect from minimized power consumption

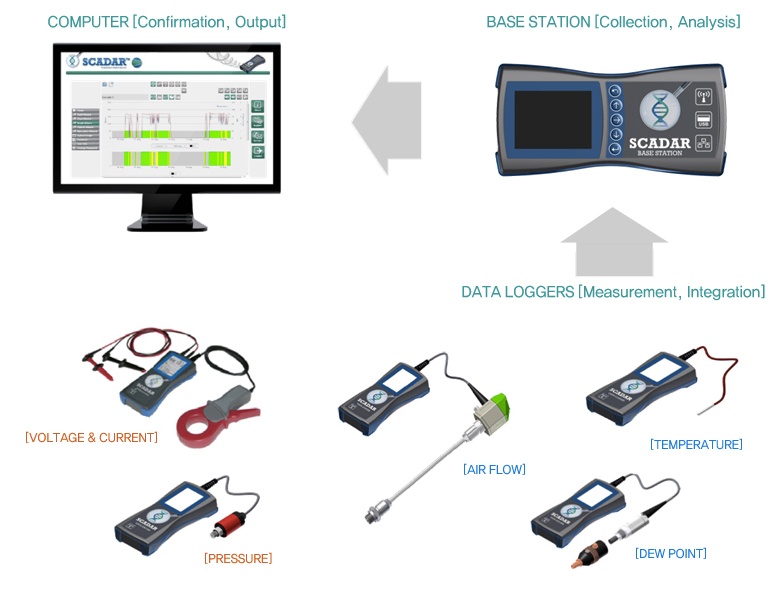

SCADAR SYSTEM Measuring Equipment

OPTION: AIR VOLUME, TEMPERATURE, DEWPOINT

*Our company possesses all of the above measuring equipment for precise measurement.

Components of SCADAR SYSTEM

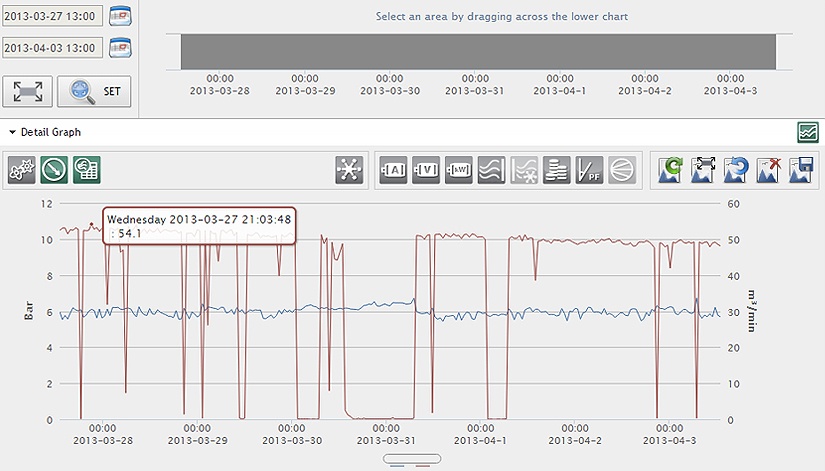

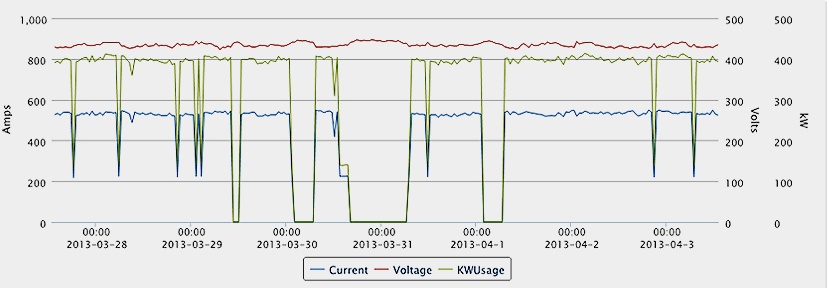

Measurement Data

We select your compressed air and pressure based on accurate measurement data for each time period, providing a service for optimal compressed air system.

Pressure & Flow Data

Current Power & Voltage Data

Energy Reduction Examples of Inverter Air Compressor

Manufacture of construction equipment parts [energy reduced by about 26%]

- Installed model: AS 120V(2 SETS)

- Installation date: January 2013

- Energy reduction expected after installation of a 100-horsepower inverter compressor and operating number management system in an existing manufacture line (expected reduction rate over 15%)

Painting and short industry [energy reduced by 15%]

- Installed model: AS 101v(1 SET)

- Installation date: March 2013

- Energy reduction expected after new installation of a 100-horsepower inverter compressor in an existing manulacture line and improvement on pipe leak (expected reduction rate over 20%)

Manufacture of machinery and gears[energy reduced by about 15%]

- Installed model:AS 101V(1 SET)

- Installation date: February 2014

- As a result of measuring energy consumption after installation of 100-horsepower inverter compressor and operating number management system ina new manufacture line, annual energy reduction of about 8,000,000 won was achieved

Manufacturer of automobile parts[energy reduced by 20%]

- Installed model: AS 101V(2 SETS)

- Installation date: April 2014

- As a result of measuring energy consumption after installation of 100-horsepower inverter compressor and operating number management system in a new factory, annual energy reduction